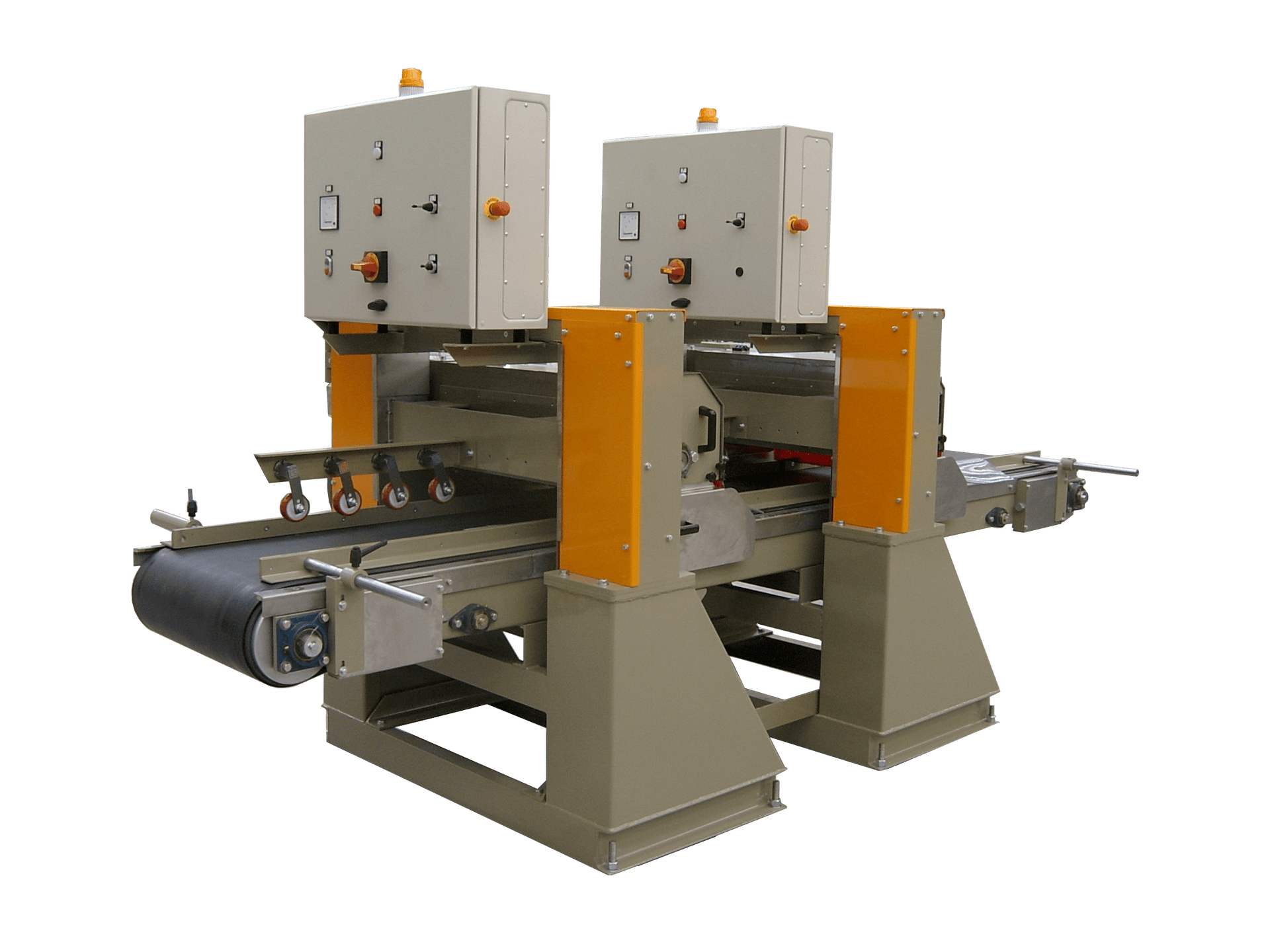

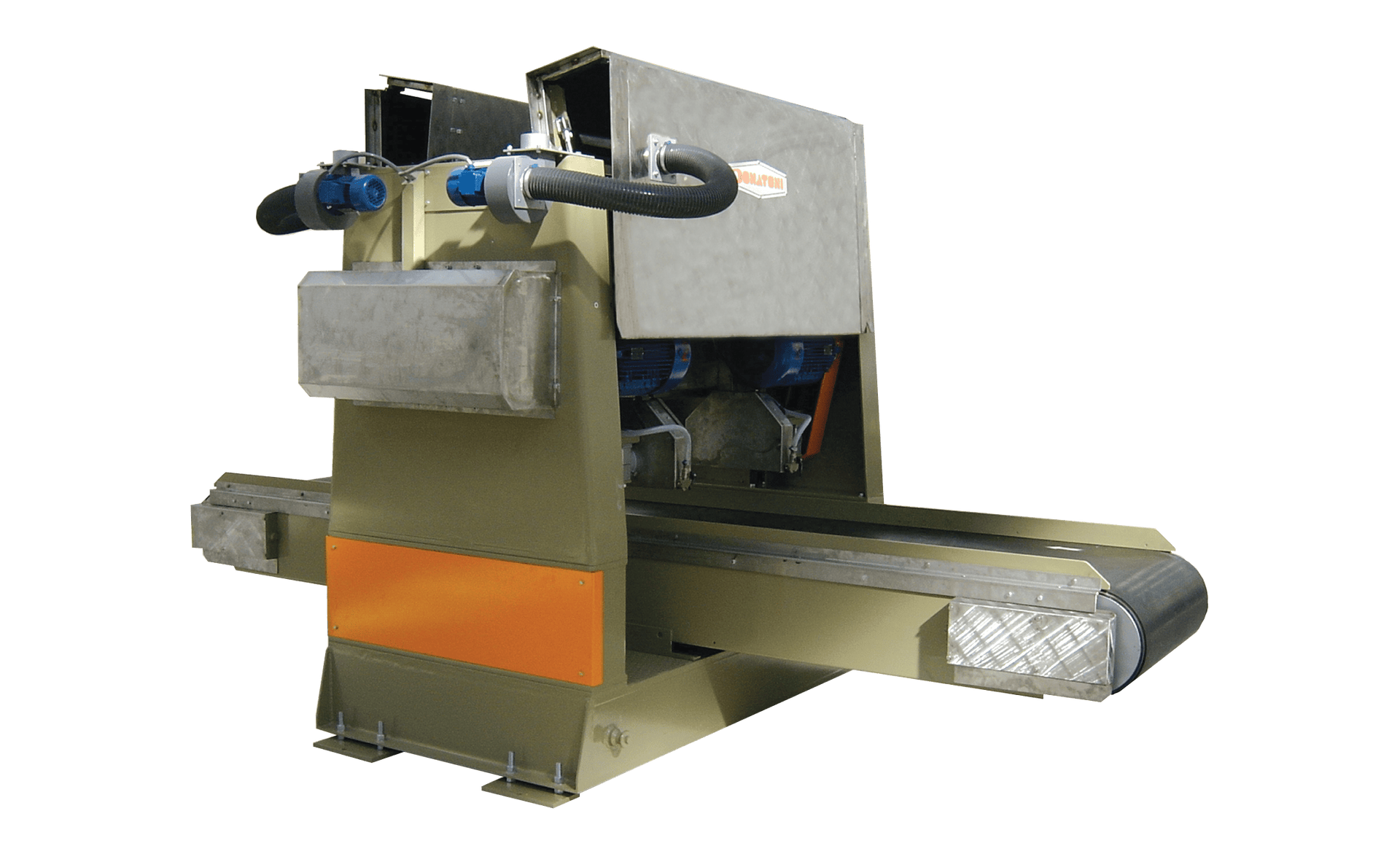

RD-2P

Heavy double spindle trimming machine

The DONATONI RD-2P trimming machines with 2 spindles are designed to make longitudinal cuts on marble tiles and strips of thick and hard stones.

Multiblade

Step cutting

Monospindle

| TYPE | RD-2P/30 kW | RD-2P/55 kW |

|---|---|---|

| Useful cutting width | 610 mm | 610 mm |

| Table useful length | 4100 mm | 4100 mm |

| Number of spindle units | 2 | 2 |

| Number of blades | max 6 per ogni mandrino | max 6 per ogni mandrino |

| Maximum blades diameter | 400 mm | 400 mm |

| Maximum cutting thickness | 100 mm | 100 mm |

| Sled or carrying spindle/motor bridge vertical travel | 100 mm | 100 mm |

| Blade/blades motor power | 30kW ciascuno | 55 kW ciascuno |

| Belt motor power | 0.55 kW | 0.55 kW |

| Installed power | 61 kW | 112 kW |

| Water consumption | 90 l/min cad. | 90 l/min cad. |

| Overall dimensions | 4400 x 2400 x 1600/h mm | 4400 x 2400 x 1600/h mm |

| Machine weight | 4750 kg circa | 5000 kg circa |

RD-2P trimming machines:

- they consist of double horizontal, separate diamond-studded disk-bearing spindles;

- they allow rapid replacement of the arbors complete with all disks, equipped with spacers between disks, by opening the top of the structure and thanks to machine special design;

- they have their support surface made of a single motorized rubber belt with adjustable feed speed depending on the thickness and the type of workpiece;

- their special structure is designed to process slabs with surfaces larger than the size of the table;

- they have perfect sawing precision thanks to special lateral belt guide devices;

- the disk spindle motors are positioned where they are protected as much as possible from processing waste and jets of water, guaranteeing safety, durability and reliability;

- they permit each spindle bridge to lift and lower to adjust cutting depth and compensate for diamond disk diameters and wear;

- they are supplied complete with a lateral workpiece guide bar that can be regulated in width and equipped, in its feed section, with pressers that keep the workpiece adherent to the belt and pressed against the guide bar;

- they offer full control by machine operators of all machine controls of each spindle (spindle support locking controls, disk depth adjustment, guide bar position).

- they have a solid and robust structure that allows the use of engines with powers up to 55 kW;

- thy have the disc spindle motors positioned so as to be as much as possible protected from possible processing residues and water jets, ensuring safety, durability and reliability.

- they consist of double horizontal, separate diamond-studded disk-bearing spindles;

- they allow rapid replacement of the arbors complete with all disks, equipped with spacers between disks, by opening the top of the structure and thanks to machine special design;

- they have their support surface made of a single motorized rubber belt with adjustable feed speed depending on the thickness and the type of workpiece;

- their special structure is designed to process slabs with surfaces larger than the size of the table;

- they have perfect sawing precision thanks to special lateral belt guide devices;

- the disk spindle motors are positioned where they are protected as much as possible from processing waste and jets of water, guaranteeing safety, durability and reliability;

- they permit each spindle bridge to lift and lower to adjust cutting depth and compensate for diamond disk diameters and wear;

- they are supplied complete with a lateral workpiece guide bar that can be regulated in width and equipped, in its feed section, with pressers that keep the workpiece adherent to the belt and pressed against the guide bar;

- they offer full control by machine operators of all machine controls of each spindle (spindle support locking controls, disk depth adjustment, guide bar position).

- they have a solid and robust structure that allows the use of engines with powers up to 55 kW;

- thy have the disc spindle motors positioned so as to be as much as possible protected from possible processing residues and water jets, ensuring safety, durability and reliability.

Double spindle trimming machine

The DONATONI trimming machine type RMG-2P for longitudinal single-pass cuts of different types of material, of different thickne...

RMG-2P

See product

Heavy multiblade trimming machine

FL linear trimming machines are part of the wide range of trimming machines designed and built by DONATONI for single-pass lengt...

FL

See product

Multiblade trimming machine with independent units

The DONATONI multiple blade trimming machines type R4E are designed for single-pass longitudinal cutting of strips an...

R4E

See product

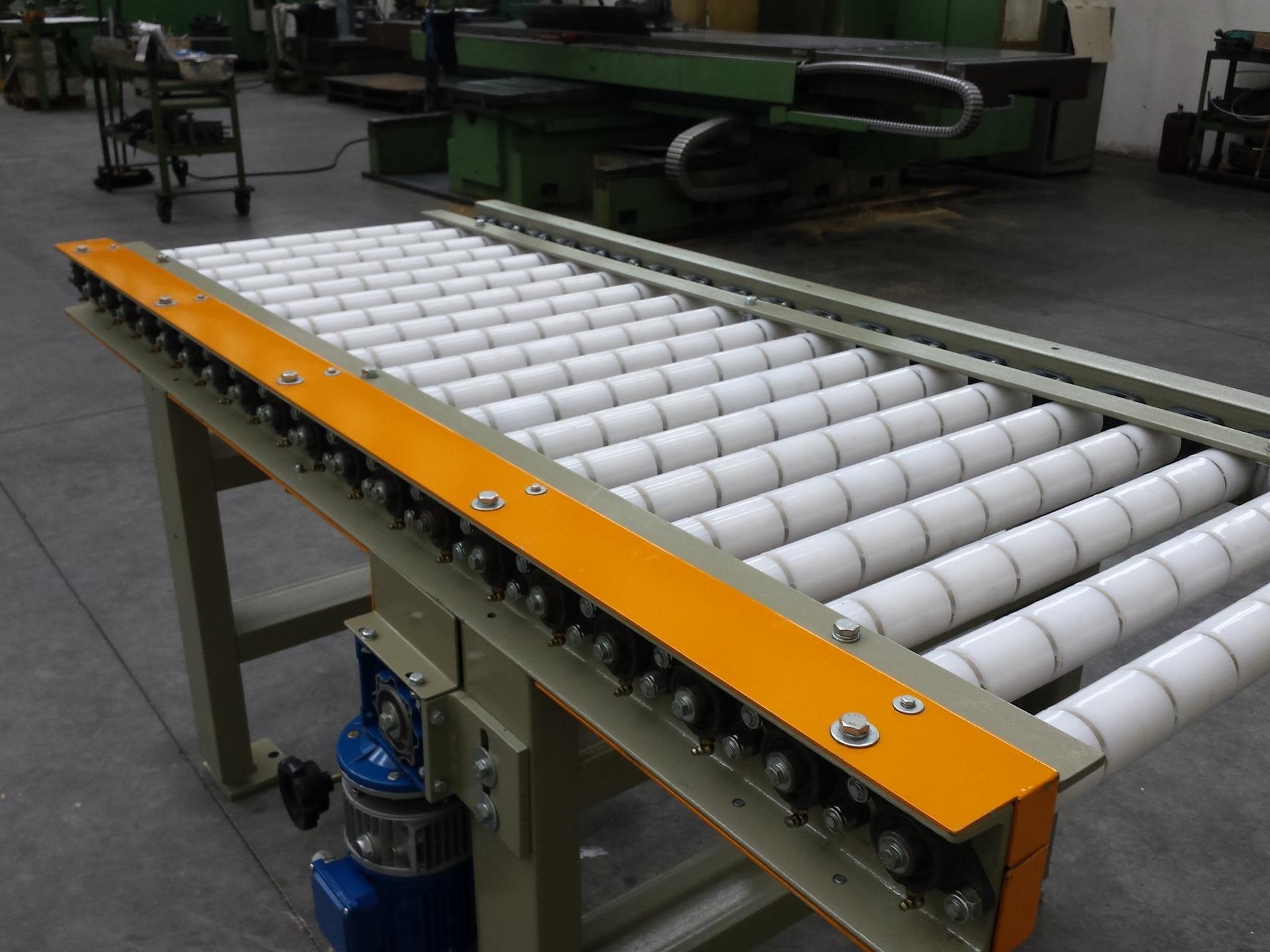

Idle roller, motorized roller or roller with clutch in nylon or stainelss steel

The DONATONI range of accessories includes:

Idle roller conveyors, motorized or frictioned with nylon, steel or PVC rol...

PR

See product

Request information

Costruzioni Meccaniche DONATONI s.r.l.

Località Montean, 9

37010 Cavaion Veronese - Verona

info@donatoni.com | sales@donatoni.com

Phone number: +39 0456260275