SC2

Splitting machine

The DONATONI SC2 splitting machine is designed to split marble and granite workpieces with MAX 150 mm widths. It makes high precision cuts of specific products (such as skirtings, inserts, samples, etc.).

Multiblade

| TYPE | SC2/2G | SC2/4G | SC2/6G |

|---|---|---|---|

| Useful cutting width | 75 - 150 mm | 75 - 150 mm | 75 - 150 mm |

| Table useful length | 3500 mm | 3500 mm | 3500 mm |

| Number of spindle units | 2 | 4 | 6 |

| Maximum blades diameter | 400 mm | 400 mm | 400 mm |

| Maximum cutting thickness | 30 mm | 30 mm | 30 mm |

| Obtainable minimum thickness | 7 mm | 7 mm | 7 mm |

| Blade/blades motor power | 7.5 kW ciascuno | 7.5 kW ciascuno | 9 kW ciascuno |

| Belt motor power | 0.75 kW | 0.75 kW | 0.75 kW |

| Water consumption | 20 l/min ciascuno | 20 l/min ciascuno | 20 l/min ciascuno |

| Machine weight | 2600 kg circa | 2800 kg circa | 3000 kg circa |

| Overall dimensions | 3750 (5800) x 1900 x 1800/h mm | 3750 (5800) x 1900 x 1800/h mm | 3750 (5800) x 1900 x 1800/h mm |

SC2 splitting machines:

- they are sturdy and compact, encased with guards that reduce noise, retain process water and ensure operator safety;

- they are composed of two flanks housing the opposed spindle units positioned vertical with respect to the cutting surface so that the machine operator can supervise the process;

- the cutting precision is guaranteed because the spindles remain stationary and adjustment of thickness is possible through vertical table motion, shown on a specific display;

- marble workpieces can be cut using 4 spindle units; granite and hard stones can be cut using 6 spindle units;

- a device automatically slows down conveyor belt speed during the cutting process whenever any of the cutting units exceeds the safety limit;

- the granite model includes, on entry, a motorized pneumatic presser unit that makes the workpieces adhere strongly to the table so that cutting disks can press on the material with greater force;

- they can be equipped with an inverter for special marble and granite cutting requirements in order to adjust spindle unit RPMs;

- on request, the machine can be equipped with approximate 1 meter long entry and output idle roller tables.

- they are sturdy and compact, encased with guards that reduce noise, retain process water and ensure operator safety;

- they are composed of two flanks housing the opposed spindle units positioned vertical with respect to the cutting surface so that the machine operator can supervise the process;

- the cutting precision is guaranteed because the spindles remain stationary and adjustment of thickness is possible through vertical table motion, shown on a specific display;

- marble workpieces can be cut using 4 spindle units; granite and hard stones can be cut using 6 spindle units;

- a device automatically slows down conveyor belt speed during the cutting process whenever any of the cutting units exceeds the safety limit;

- the granite model includes, on entry, a motorized pneumatic presser unit that makes the workpieces adhere strongly to the table so that cutting disks can press on the material with greater force;

- they can be equipped with an inverter for special marble and granite cutting requirements in order to adjust spindle unit RPMs;

- on request, the machine can be equipped with approximate 1 meter long entry and output idle roller tables.

Horizontal splitting machine

The DONATONI SC3 splitting machine cuts marble strips and tiles horizontally into two parts.

...

SC3

See product

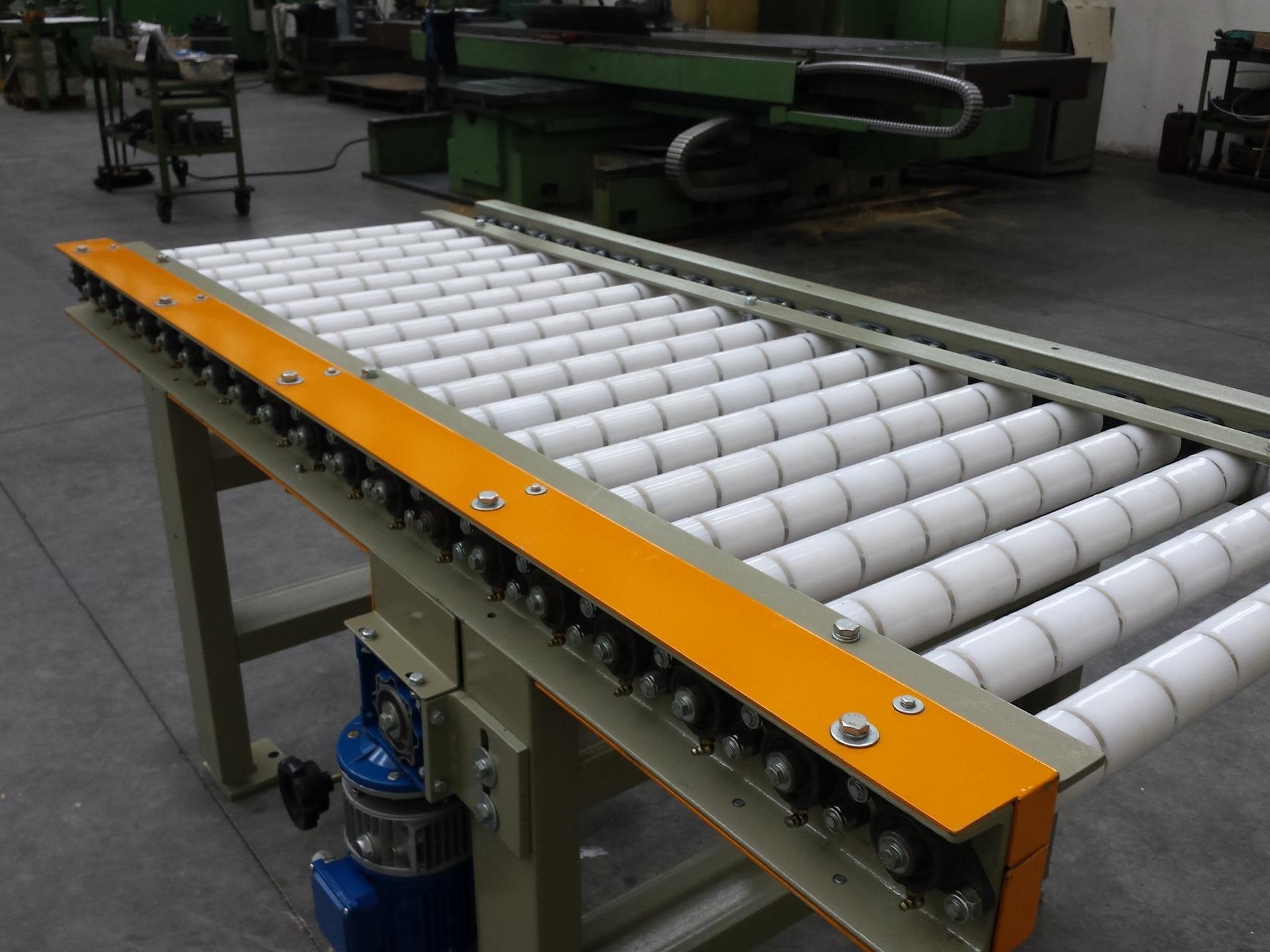

Idle roller, motorized roller or roller with clutch in nylon or stainelss steel

The DONATONI range of accessories includes:

Idle roller conveyors, motorized or frictioned with nylon, steel or PVC rol...

PR

See product

Request information

Costruzioni Meccaniche DONATONI s.r.l.

Località Montean, 9

37010 Cavaion Veronese - Verona

info@donatoni.com | sales@donatoni.com

Phone number: +39 0456260275

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)