E1S

Automatic multiblade cross cutting machine

The main features of the DONATONI E1S multispindle crosscutting machine are the great precision and high productivity in transversal cutting, with single or multiple passes, of strips of different materials. Thanks to the installed technology, cutting takes place in a continuous automatic cycle with controlled positioning of the cutting units.

Multiblade

Automatic

OPTIMIZATION SOFTWARE

| TYPE | E1S/VL | E1S/VP |

|---|---|---|

| Useful cutting width | 610 mm | 610 mm |

| Table useful length | 3150 mm | 3150 mm |

| Minimum cutting length between blades | 150 mm | 250 mm |

| Number of spindle units | 2-4 | 2-4 |

| Maximum blades diameter | 350 mm | 400 mm |

| Maximum cutting thickness | 30 mm | 80 mm |

| Disks spindle motor power | 5,5 kW per disco | 9 kW per disco |

| Spindle/s travel motor power | 1,5 kW | 1,5 kW |

| Spindle unit/s lateral movement motor power | 0,3 kW(0,7 kW BSH) per gruppo | 0,3 kW(0,7 kW BSH) per gruppo |

| Belt motor power | 1,5 kW | 1,5 kW |

| Water consumption | 10 l/min per gruppo | 10 l/min per gruppo |

| Compressed air consumption | 5 l/min per gruppo | 5 l/min per gruppo |

| Machine weight | 5000 kg circa | 5000 kg circa |

| Overall dimensions | 4650 x 2200 x 1900/h mm | 4650 x 2200 x 1900/h mm |

E1S cropping machines:-

- Guide for material alignement and fixing

- Great precision in cutting

- Advanced algoritms for optimizing production

- Real-time control of the machine status and 4.0

- Guide for material alignement and fixing

- Great precision in cutting

- Advanced algoritms for optimizing production

- Real-time control of the machine status and 4.0

Automatic cross cutting machine

DONATONI APL cross-cutting machines allow single pass cutting of material with a thickness up to 100 mm (APLX version) and 200 m...

APL

See product

Cutting systems with material laser selection

DONATONI machines can be equipped with accessory applications, such as cutting systems with material laser selection, type L.&nb...

L

See product

Cutting systems with automatic detector for size and cutting areas

The DONATONI automatic cross cutting machines can be equipped with an accessory application, such as the cutting system with aut...

T

See product

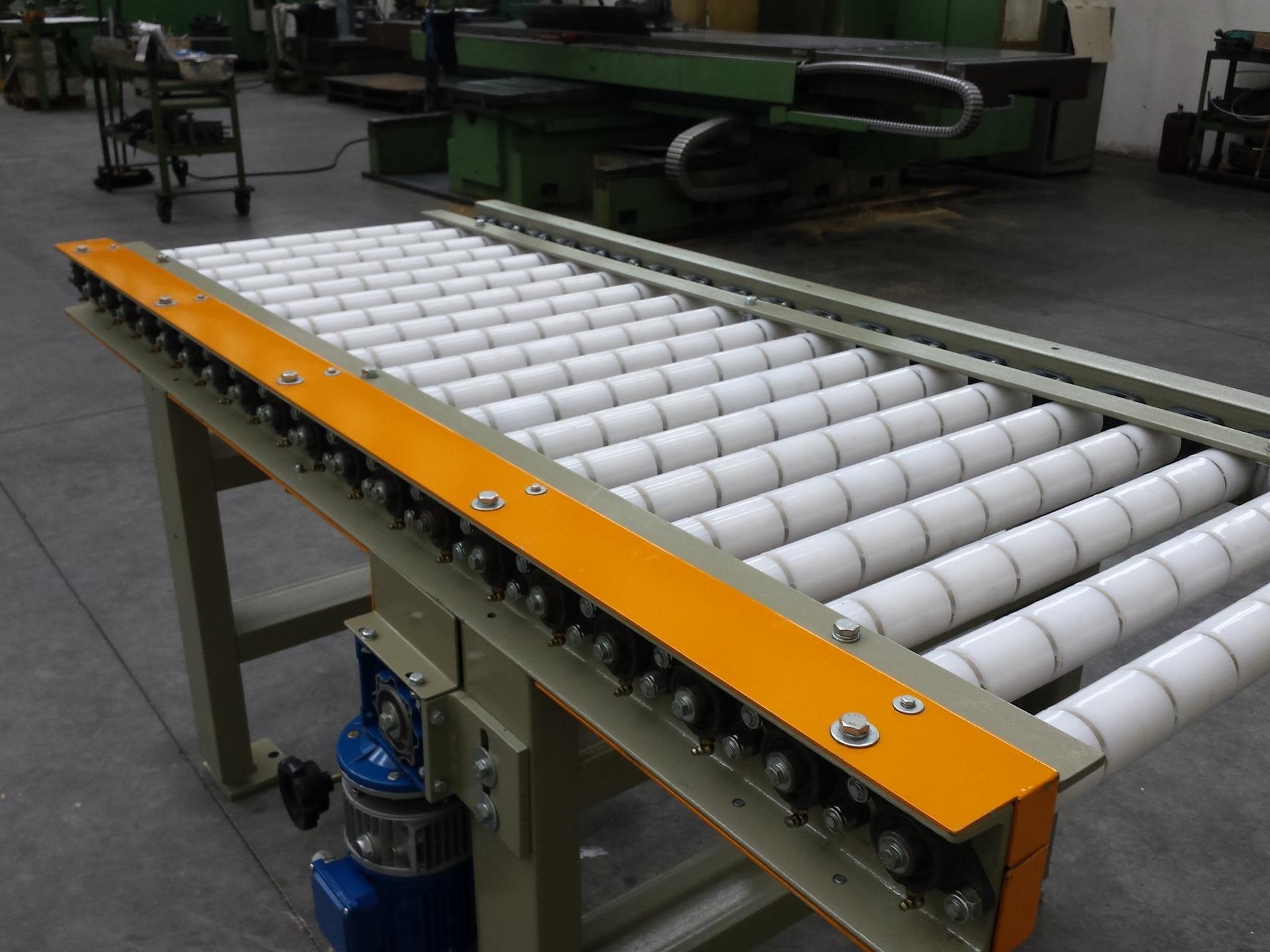

Idle roller, motorized roller or roller with clutch in nylon or stainelss steel

The DONATONI range of accessories includes:

Idle roller conveyors, motorized or frictioned with nylon, steel or PVC rol...

PR

See product

Request information

Costruzioni Meccaniche DONATONI s.r.l.

Località Montean, 9

37010 Cavaion Veronese - Verona

info@donatoni.com | sales@donatoni.com

Phone number: +39 0456260275